Thanks to some funds from the Creative and Cultural Industries Exchange, University of Leeds, I’ve had the pleasure of a week’s research residency within Access Space in Sheffield, working within the highly creative environment of their fabrication/maker lab, to really get to grips with the ancient technology of the warp weighted loom, within the context of advanced digital manufacture.

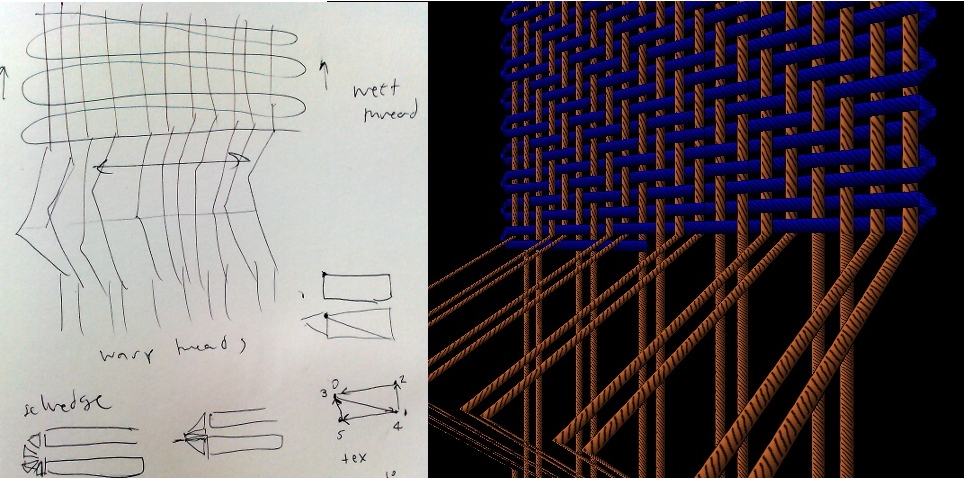

This was a bit of a chicken-and-egg situation; I hadn’t really woven anything before, but wanted to make my own loom to learn on. Ellen suggested just lashing together four sticks and jumping in, which is what I did:

This loom was pretty terrible to use; wobbly, and I knew that making heddles out of paperclips was a bad idea, they constantly got caught on the wrong threads. But, I needed to learn from failure at this point, and despite all chance to fail, managed to weave (and unweave) a small piece of fabric. What I enjoyed most was tying the thread evenly spaced across the top beam for the warp threads to hang from. I’ve done a lot of knitting in the past, and this felt a lot like casting on. The knowledge for doing this was already in my fingers, a surprise to feel it there which made the confidence flow.

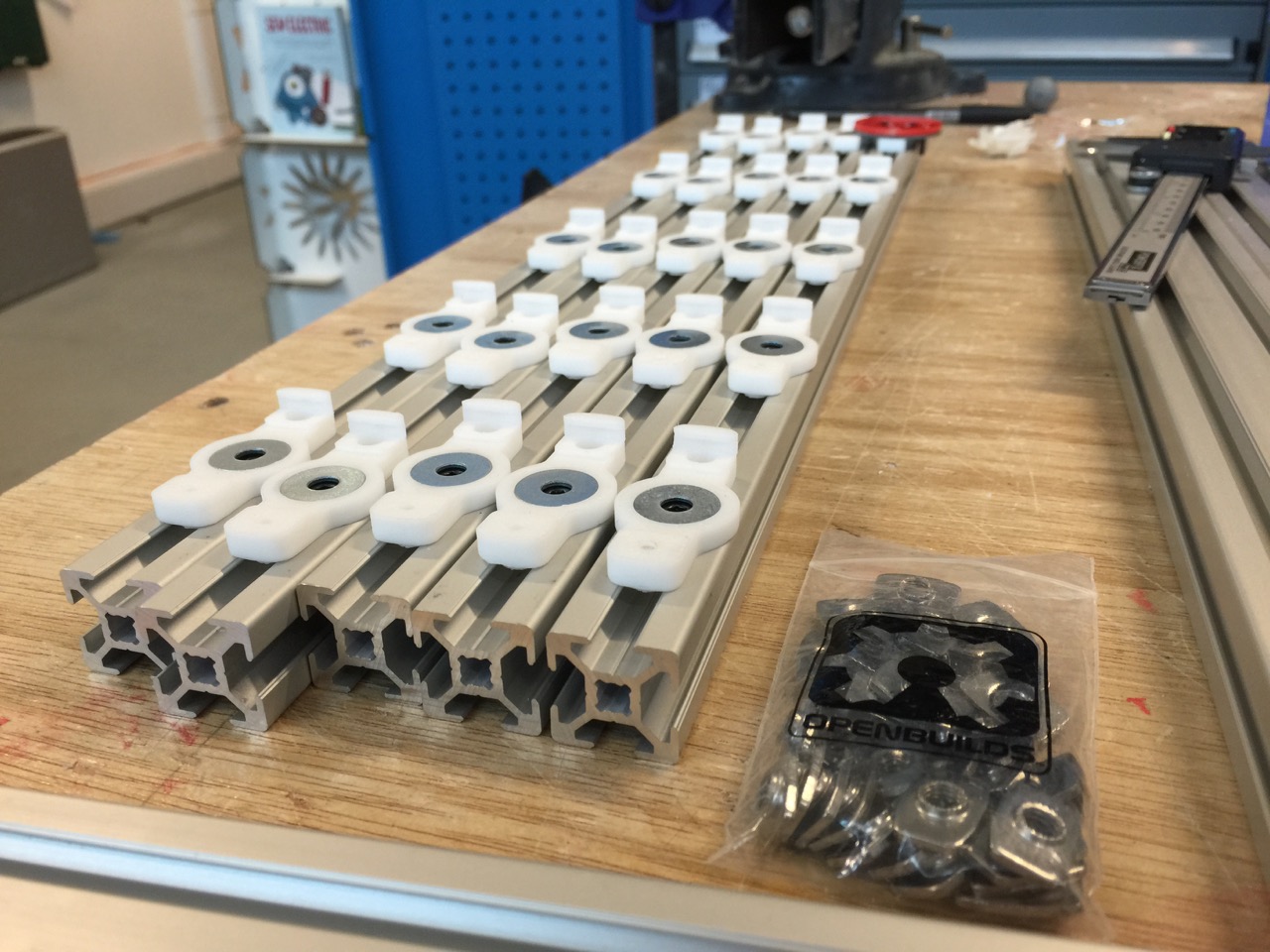

Next was the actual residency, beginning with an induction on lasercutting with John Moseley, my technical and engineering support for the week.

I was a bit worried about jumping into laser cutting, that making things via computer-aided design would distance me from the material. At least with the way John encouraged me to work, this did not turn out to be a problem at all. I sketched out some ideas, and then when straight to the laser cutter to see how they worked. This connected my thought and design processes with the material and the way of making, considering the order of cut, how to avoid cut pieces pivoting and blocking the laser, how the stickiness of the burnt MDF would help or hinder what I’m doing, and so on.. More than all this just holding the pieces in my hands made so much clear and avoided so much theoretical wrangling.

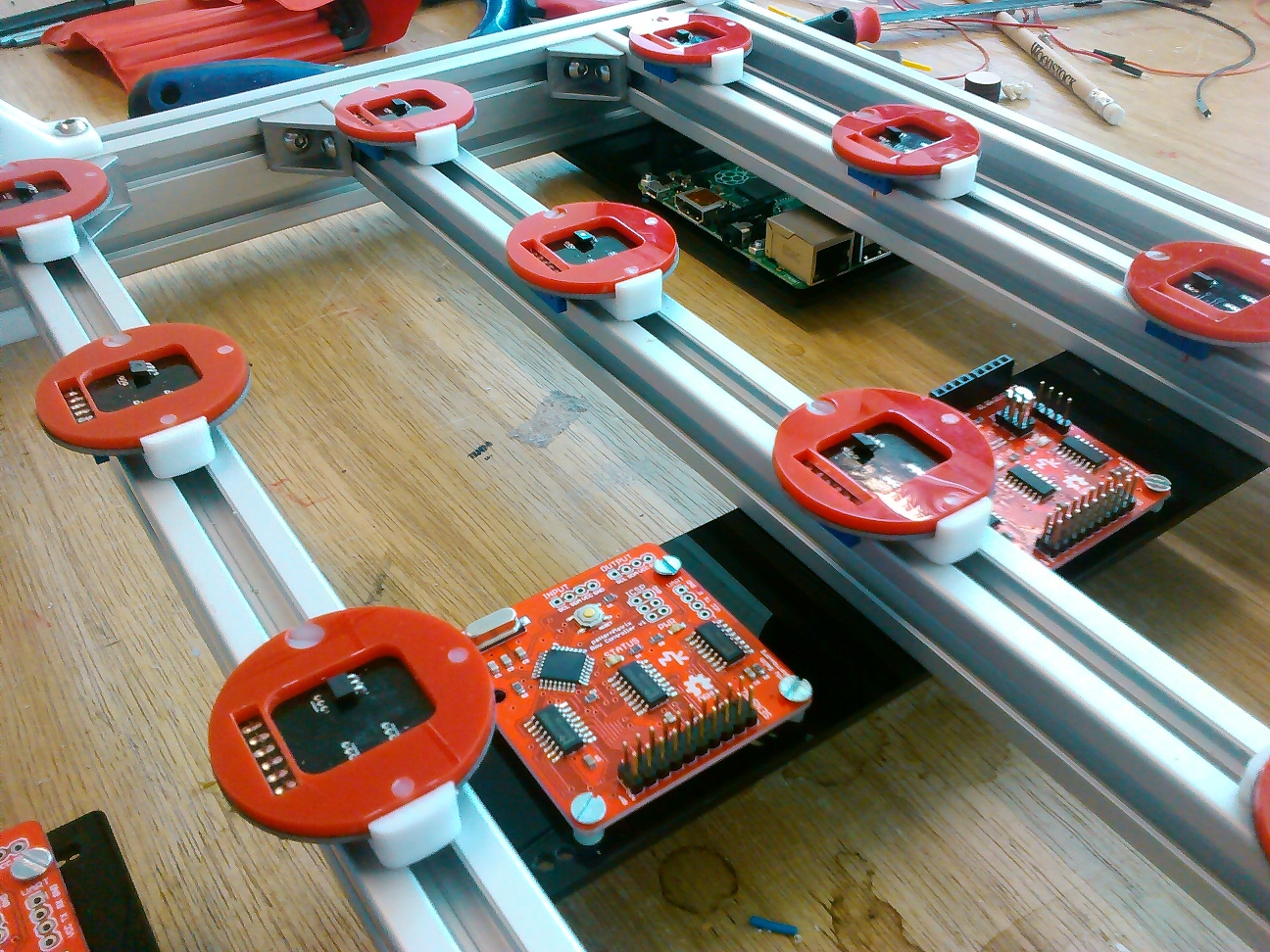

Within a couple of days I had a nicely balanced single-shaft loom with space for a camera and projector to be mounted:

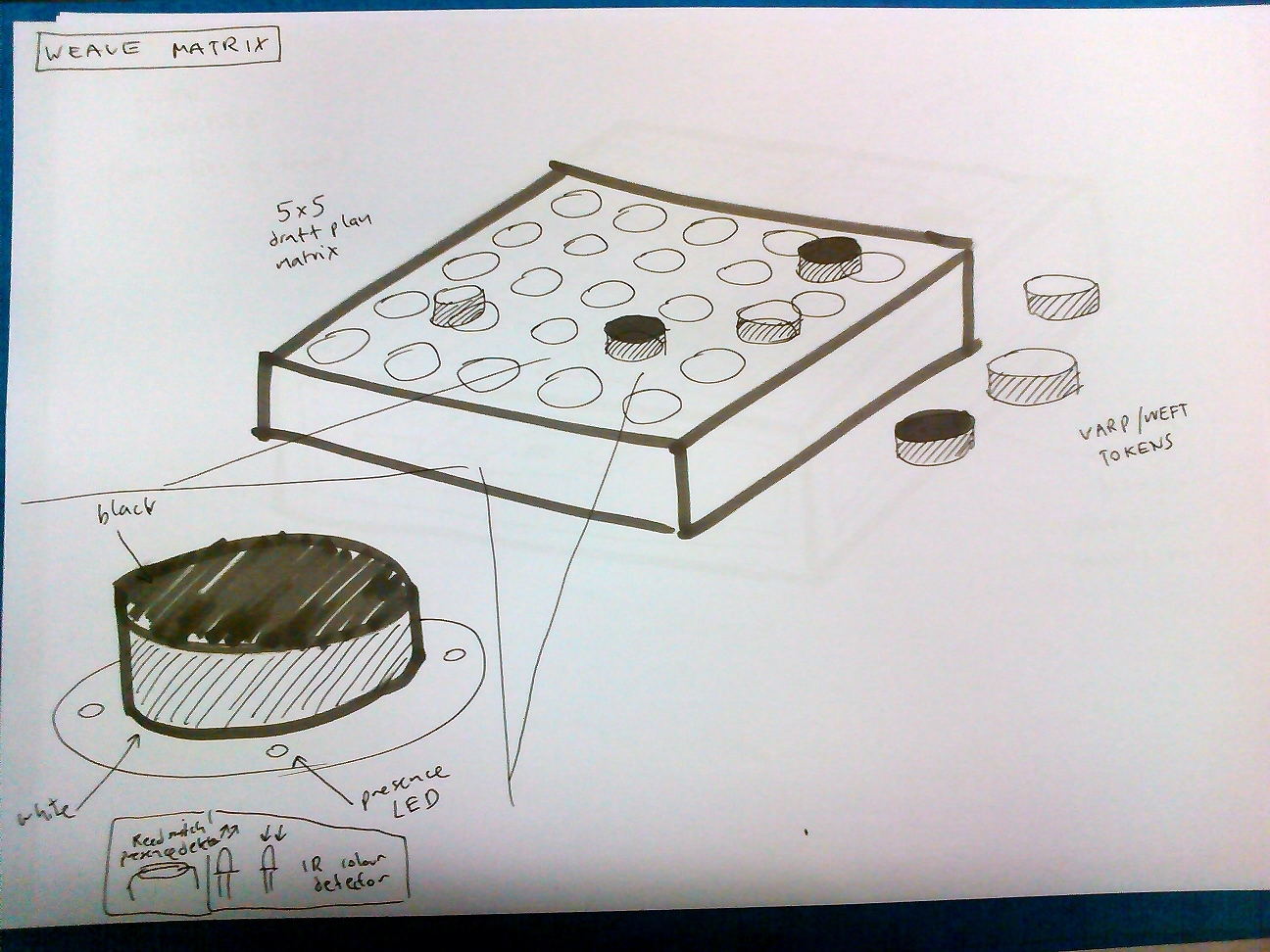

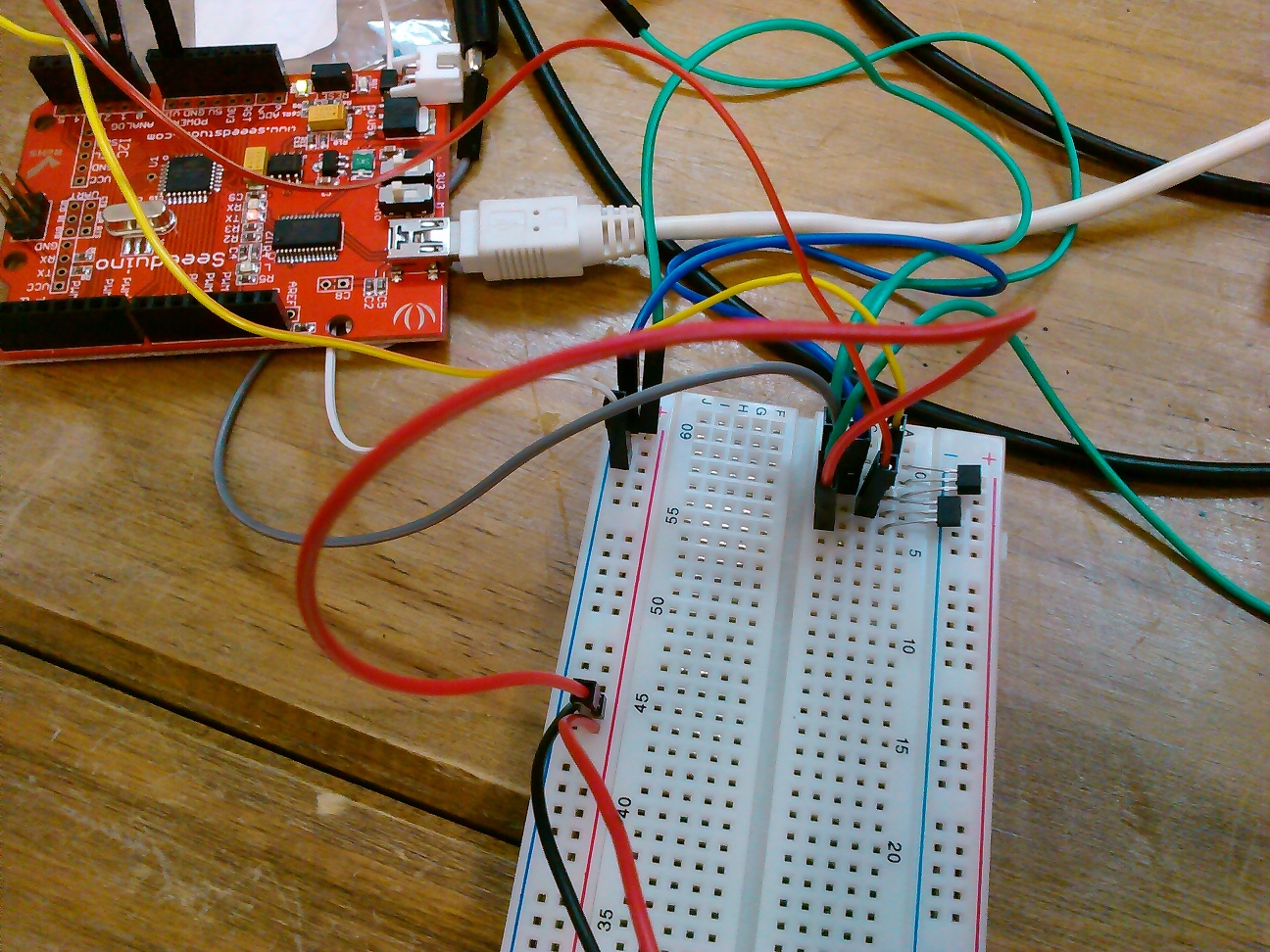

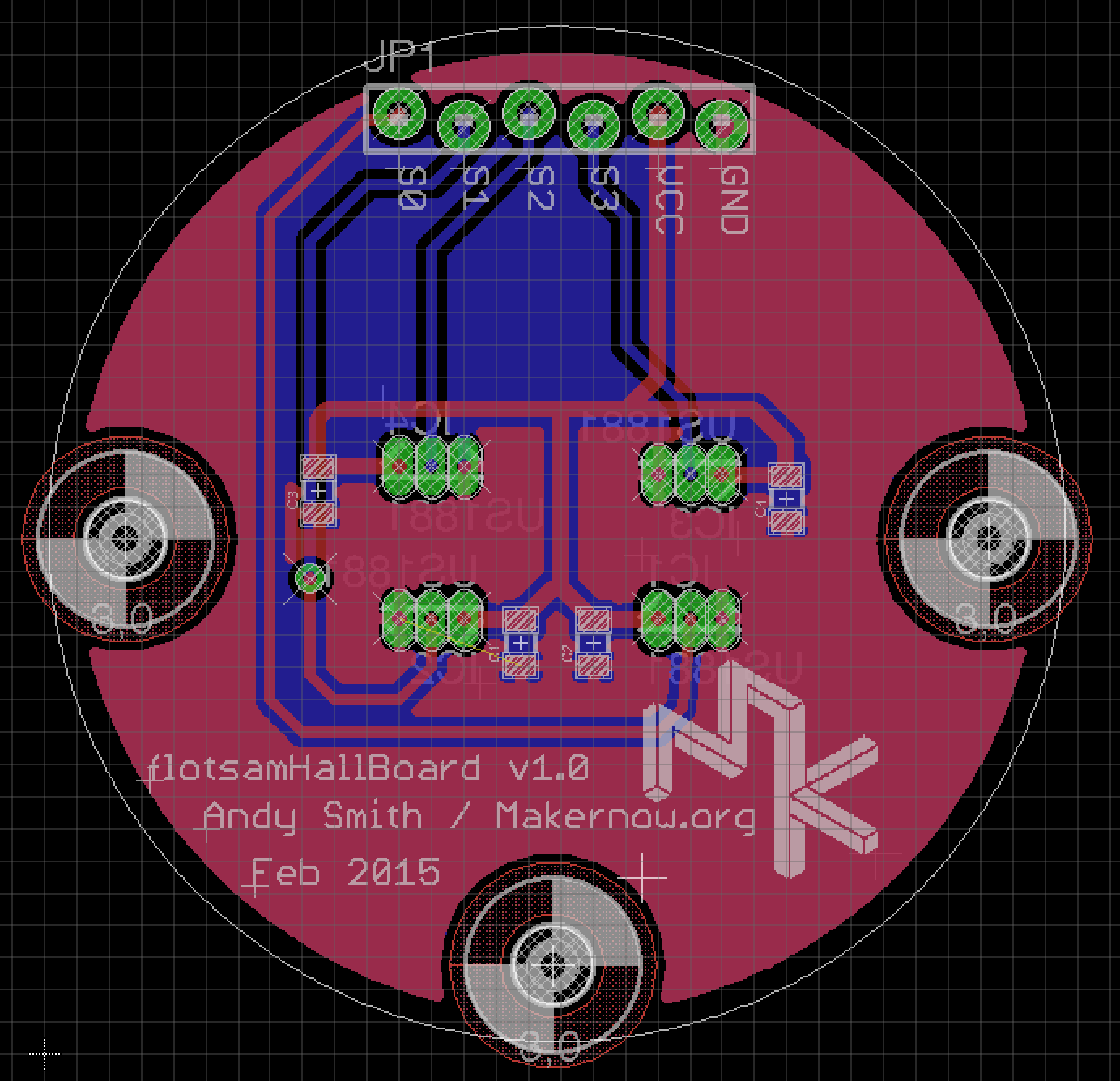

The focus of the residency was not only to make a loom, but experiment with how it could be ‘augmented’ with contemporary technology. This is a bit of a tightrope, because the warp weighted loom is excellent, well developed technology which does not really need augmenting. Nonetheless, despite sometimes ending up in the domain of heritage, I think the nature of craft is not to stay still but to be alive and personal, and it felt right to make a loom customised for myself, and look for ways of extending it with additional sensory apparatus.

Tying the heddles came less naturally to me, I managed to make some more or less the same length by spacing them using two dowels.

Then straight into some actual weaving, making some plain weave:

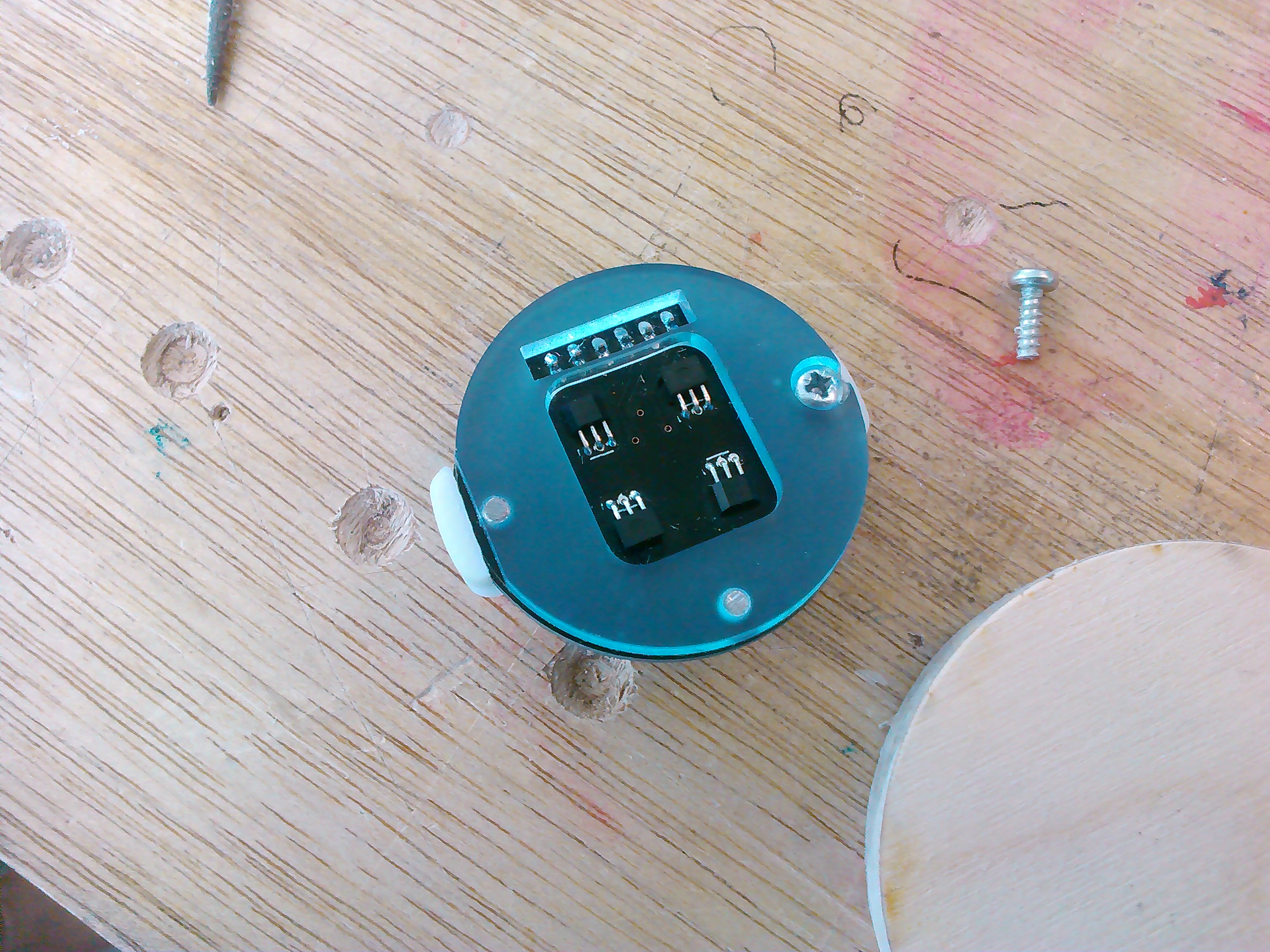

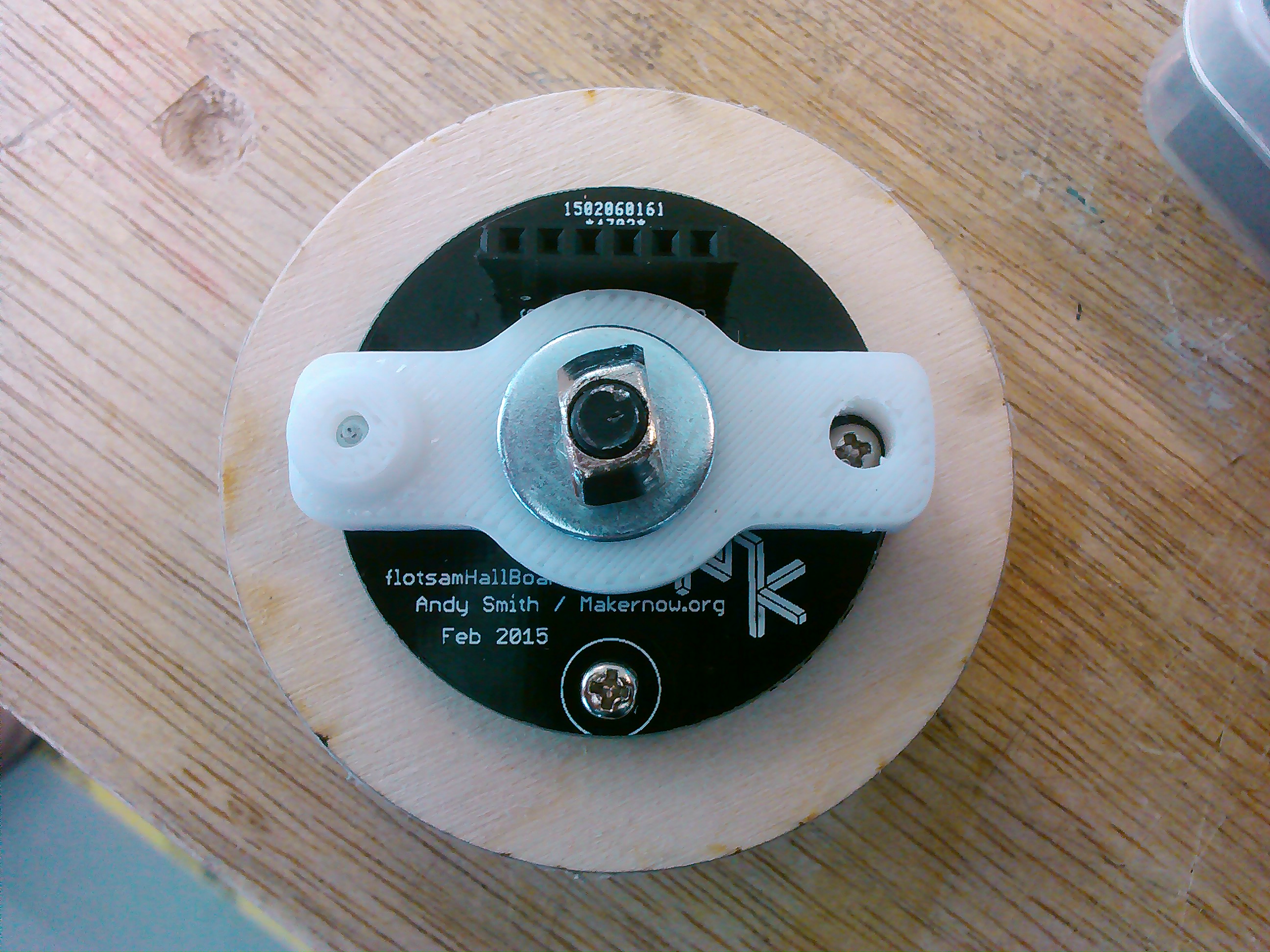

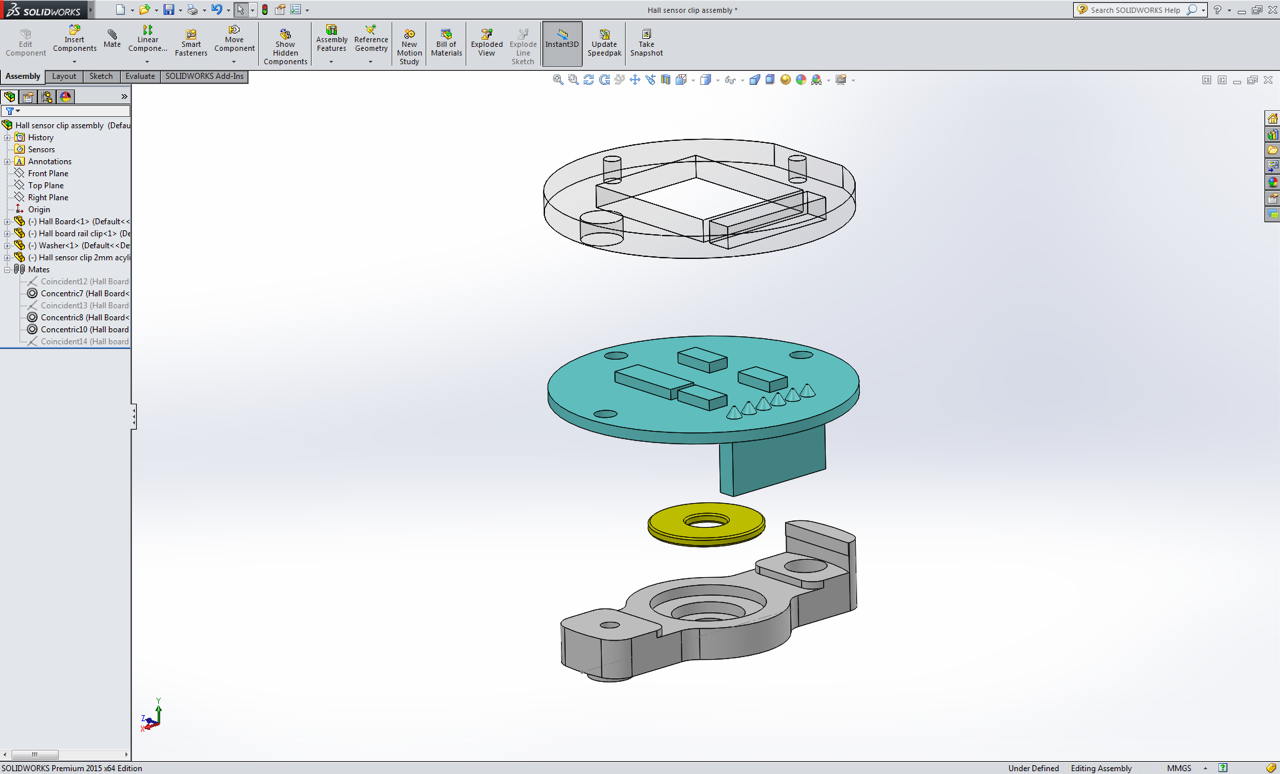

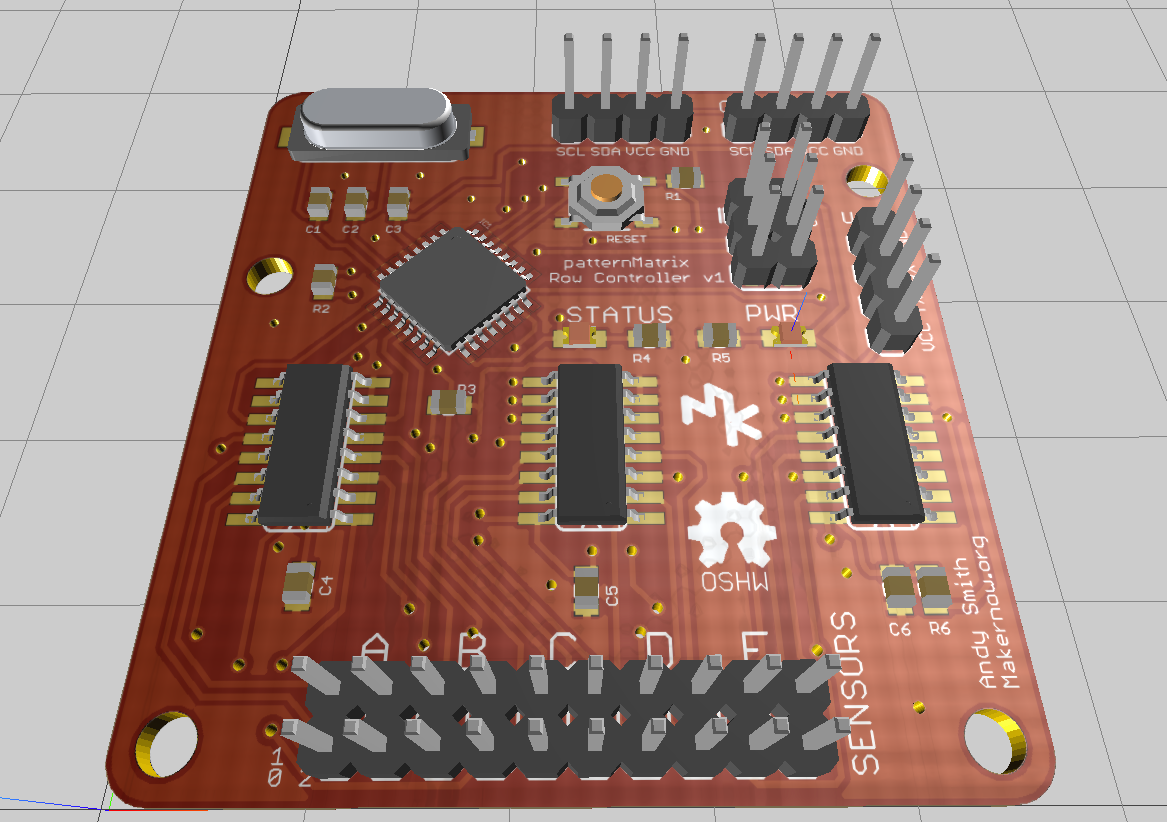

As you can see I used some of access space’s hex nuts for weights, five per thread. I used a ruler to beat in the thread. The little symbols on the front are fiducials which might help with future computer vision experiments.

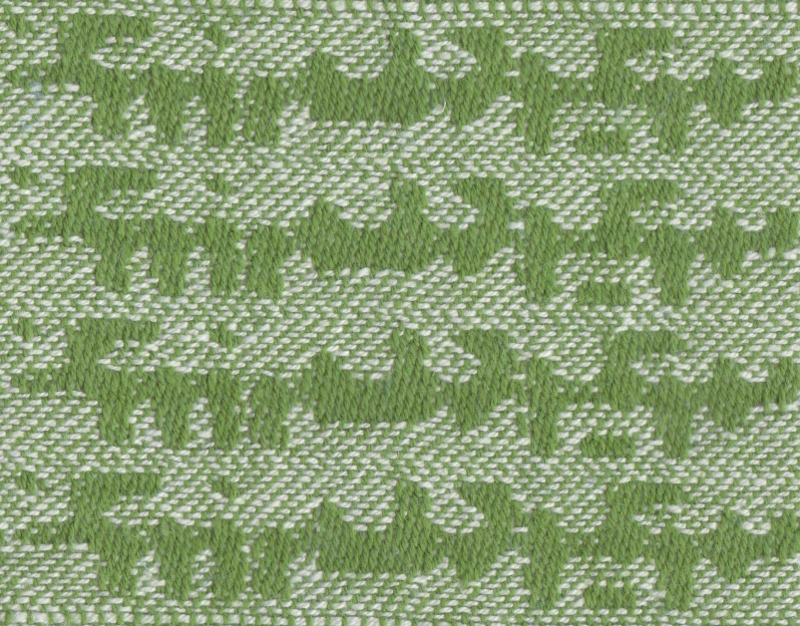

Here’s my first weave on the loom:

https://www.youtube.com/watch?v=LNlOAYWBe0M

The fabric I ended up with charts my learning, starting off messier, getting better, then worse again as I try out different techniques, for example beating in the thread with the shed open and then again with it closed, through the counter shed. I’d like to keep the fabric I made, but in the spirit of live coding, I’ll probably unweave it.

Next directions include:

- Adding more shafts!

- Developing a programming language for describing/generating/exploring weave structures and loom configurations

- Exploring projection mapping with a camera and projector to project the structure onto the fabric

- Exploring picking without shafts, vibrating the strings (e.g. using wireless controlled motors in the warp weights) to indicate which goes over vs under

- Exploring unweaving – can this be automated? It would be great if the loom could automatically unweave whenever it isn’t being used. Ellen will have some thoughts on this I’m sure

- Releasing the laser cut source files with a creative commons license

- Developing a workshop where people construct and use their own loom

- Seeing if the loom can be used as a musical instrument

- more to come…

I’ll explore projection mapping, buzzing and sensors on the final day of my residency. For now I’m really pleased with what I’ve achieved so far in Access Space, I already have a warp weighted loom design that can be cut in minutes at very little cost, that fits in the laptop section of my bag, is sturdy, well balanced and a fantastic framework (literally, and theoretically) for ongoing research. I really recommend these residencies for other researchers who want some time outside their institution to work with material, it’s opened things up for me.

The CCI Exchange funds will also pay for some related events and workshops at Access Space, follow them on facebook or twitter if you’re in the Sheffield area to stay up to date.